Controller DEI 617D

sumber: https://hvactutorial.files.wordpress.com/2011/08/617s-617d.pdf

perangkat yang mirip:

Front Panel Operating

1.Power ON/OFF button :

Press button and hold for 3 seconds to star-tup the controller based on the preset operating mode

a parameters. Press it again for 3 seconds to turn off the system.

2.

nd

Light ON/OFF button :

Press button and hold for 3 seconds to turn on or off the the illuminating equipment. In model DEI-

617D, it serves to switch between upper & lower lights on or off.

3.Defog ON/OFF button :

Press button and hold for 3 seconds to turn on or off the defog heater.

4.Manual/Stop defrost :

Press both & buttons and hold for 3 seconds to enter defrost process which will be

terminated automatically when the p g again both & buttons.

5.Lock/unlock panel parameters :

In normal operating, press both Light and Defog buttons for 3 seconds to lock the parameters

("00" is displayed) or to unlock ("33" is displayed).

6.User`s parameter setup :

A.Press Func. button for 3 seconds to enter the User s Parameter Setup Mode, and the Set

Temp. LED is on.

B.Press the Func. button again to select sequentially from the 4 functions a/f : Set Temp., Set temp.

threshold, Operation duty and Defrost time.

C.When the required function is selected, use or button to adjust the value.

D.If no more button is pressed within 10 seconds, the system will save the new value and then exit to

normal operation.

7.Internal parameter setup :

A.Stop the power. Press Func. button followed by re-plug in to enter the Internal Parameter Setup

Mode. both Light and Defog LEDs flash and Set. Temp. LED is on.

B.Press Func. Button to select sequentially from the 3 functions a/f : Set min. temp. (Set Temp.

LED on), Temp. sensor calibration ( temp. LED on), Compressor start delay time (Operation LED

on)

C.When the required function is selected, press or button to adjust the value.

D.Press both Light and Defog buttons to load in the factory default.

E.Press Power button to save the new parameter and exit to the normal operation.

8.Error codes :

"EE" : Parameter memory failure (Re-plug in and operate as factory default)

"E0" : Calibrating sensor failure (Return to the factory for repairing)

"E1" : Probe failure (Check if the sensor is well connected or change the sensor)

reset defrost time is up or by pressin

M icom C ontroller

Power ON/OFF button

Setting temperature LED

Temperature threshold LED

Defrost time LED

Operation duty LED

Temperature / time decrease button Numerical display

Temperature / time increase button

Light ON / OFF button

Defog ON / OFF button

Function select button

Light LED

Defog LED

617S/617D OPERATION MANUAL

Research/Developed Manufactured by a ISO-9001 Certificated company.

-Version 03-

Specification :

1.Temp. display range : -45 ~ +45 Tolerance +/- 1

2.Temp. sensor : NTC. PVC or silicon. 1.5m (L)

3.Parameter setup:

A.User s parameters :

a.Set temperature : Min. Set~ 40 Factory default 5 (DEI-617) or -18 (DEI-817).

b.Set temp. threshold : 2K~10K (+/- 1 ~+/- 5 ) Factory default 4K (+/-2 ).

c.Operation duty : 0~99 hours. Factory default 4 hours.

d.Defrost time : 0~60 minutes. Factory default 25 minutes.

B.Internal parameters:

a.Min. set temperature:-40 ~10 . Factory default 0 (DEI-617)or-30 (DEI-817).

b.Temp. calibration:-8 ~7 . Factory default 0 .

c.Compressor delay protection:0~15 minutes. Factory default 3 minutes(*1)

C.Factory default (unable to change):

In case of temperature sensor failure, the compressor will operate for 15

minutes and stop for 15 minutes automatically.

4.Compressor operation:The compressor starts operating when room temperature (set temp.+1/2

threshold), and will be off when room temperature ( set temp. +1/2 threshold) or in defrosting process.

5.Defrost mode and fan operation :

a.Defrost is performed by the preset defrost time or When defrost in

progress, Defr. LED flashes, compressor is off, and fan runs continuously.

b.After defrost, fan starts (*2) and compressor operates according to the difference between room temp,

setting temp. and temp. Threshold.

B.Elec. heater defrost (DEI-817)

a.Defrost is performed by the preset operation duty or forced manually. When defrost in progress, the

Defr. LED flashes, compressor is off, and heater turns on and fan stops.

b.After defrost, fan starts with 2 minutes delay (*2) and compressor with 1 minute delay, operates

according to the difference between room temp., setting temp. and temp. threshold.

6.Output contact capacity:

A.Compressor contact : N.O. contact 25A/250VA (*3)

B.Fan, Light, Defog, Heater contact : 7A/250VAC

7.Power requirement : AC220V/110V +/- 10% single phase 50/60 Hz, 10 Watts (Controller only)

8.Storage : -10~+70 , RH20%~80% (none-condensing)

9.Operating : -15~+60 , RH20%~90% (none-condensing)

*1. Even parameter value as 0 minute, the compressor still starts with 1 minute delay after re-plug in

*2. Fan's ON or OFF subject to continuous operating.(internal option)

*3. Compressor with 30A N.O contact plus 10A N.C contact is available..

A.Compressor-off defrost (DEI-617).

operating manually.

® w ¤· ºP ·¾ Ź

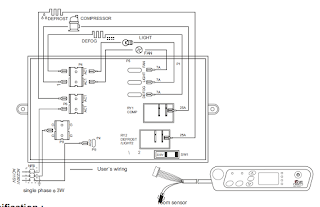

room sensor

User`s wiring

DEFOG LIGHT FAN

P4

P5

RY2

DEFROST

/LIGHT2

LIGHT

DEFOG

DEFROST COMPRESSOR

FAN

7A

P1

7A

7A

25A

25A

AC1 AC1 AC1

P6

G G

G G

P8

P9

AC1

AC2

° £ Á¹ ÷q ¼¾ ö¹ À £ Á¾ Y÷

° £ ù úq ¼¾ ö¹

· Ó © ú

· ® °

± μ¦ a½ u

· ® °

· Ó © ú

° £ Ã ú

RY1

COMP

À £ Á¾ Y÷

° £ Á\·÷Ó ©2ú

¹ q· ½2

¹ q· ½1

NFB

single phase 3W

230V SW1

~~

¶}

° £ Ã ú · Ó © ú

¶ } · Å « × ³ ] © w

· Å ® t ³ ] © w

¹ B Â à ¶ g ´ Á

° £ Ã ú ® É ¶ ¡

AC230V/

AC115V

sumber: https://hvactutorial.files.wordpress.com/2011/08/617s-617d.pdf

perangkat yang mirip:

- http://www.dei.com.tw/cool_single_e.html

- http://www.ehardware2u.com/index.php?route=product/product&product_id=1766

- https://hvactutorial.files.wordpress.com/2011/08/dei-617se-617de-817e.pdf

- https://hvactutorial.files.wordpress.com/2011/08/dei-815e.pdf

- https://hvactutorial.wordpress.com/instruction-manual/dei/

- http://www.temco.bg/p/01_electron/spec_en/DEI-615/615.pdf

- https://hvactutorial.files.wordpress.com/2011/08/617s-617d.pdf

Front Panel Operating

1.Power ON/OFF button :

Press button and hold for 3 seconds to star-tup the controller based on the preset operating mode

a parameters. Press it again for 3 seconds to turn off the system.

2.

nd

Light ON/OFF button :

Press button and hold for 3 seconds to turn on or off the the illuminating equipment. In model DEI-

617D, it serves to switch between upper & lower lights on or off.

3.Defog ON/OFF button :

Press button and hold for 3 seconds to turn on or off the defog heater.

4.Manual/Stop defrost :

Press both & buttons and hold for 3 seconds to enter defrost process which will be

terminated automatically when the p g again both & buttons.

5.Lock/unlock panel parameters :

In normal operating, press both Light and Defog buttons for 3 seconds to lock the parameters

("00" is displayed) or to unlock ("33" is displayed).

6.User`s parameter setup :

A.Press Func. button for 3 seconds to enter the User s Parameter Setup Mode, and the Set

Temp. LED is on.

B.Press the Func. button again to select sequentially from the 4 functions a/f : Set Temp., Set temp.

threshold, Operation duty and Defrost time.

C.When the required function is selected, use or button to adjust the value.

D.If no more button is pressed within 10 seconds, the system will save the new value and then exit to

normal operation.

7.Internal parameter setup :

A.Stop the power. Press Func. button followed by re-plug in to enter the Internal Parameter Setup

Mode. both Light and Defog LEDs flash and Set. Temp. LED is on.

B.Press Func. Button to select sequentially from the 3 functions a/f : Set min. temp. (Set Temp.

LED on), Temp. sensor calibration ( temp. LED on), Compressor start delay time (Operation LED

on)

C.When the required function is selected, press or button to adjust the value.

D.Press both Light and Defog buttons to load in the factory default.

E.Press Power button to save the new parameter and exit to the normal operation.

8.Error codes :

"EE" : Parameter memory failure (Re-plug in and operate as factory default)

"E0" : Calibrating sensor failure (Return to the factory for repairing)

"E1" : Probe failure (Check if the sensor is well connected or change the sensor)

reset defrost time is up or by pressin

M icom C ontroller

Power ON/OFF button

Setting temperature LED

Temperature threshold LED

Defrost time LED

Operation duty LED

Temperature / time decrease button Numerical display

Temperature / time increase button

Light ON / OFF button

Defog ON / OFF button

Function select button

Light LED

Defog LED

617S/617D OPERATION MANUAL

Research/Developed Manufactured by a ISO-9001 Certificated company.

-Version 03-

Specification :

1.Temp. display range : -45 ~ +45 Tolerance +/- 1

2.Temp. sensor : NTC. PVC or silicon. 1.5m (L)

3.Parameter setup:

A.User s parameters :

a.Set temperature : Min. Set~ 40 Factory default 5 (DEI-617) or -18 (DEI-817).

b.Set temp. threshold : 2K~10K (+/- 1 ~+/- 5 ) Factory default 4K (+/-2 ).

c.Operation duty : 0~99 hours. Factory default 4 hours.

d.Defrost time : 0~60 minutes. Factory default 25 minutes.

B.Internal parameters:

a.Min. set temperature:-40 ~10 . Factory default 0 (DEI-617)or-30 (DEI-817).

b.Temp. calibration:-8 ~7 . Factory default 0 .

c.Compressor delay protection:0~15 minutes. Factory default 3 minutes(*1)

C.Factory default (unable to change):

In case of temperature sensor failure, the compressor will operate for 15

minutes and stop for 15 minutes automatically.

4.Compressor operation:The compressor starts operating when room temperature (set temp.+1/2

threshold), and will be off when room temperature ( set temp. +1/2 threshold) or in defrosting process.

5.Defrost mode and fan operation :

a.Defrost is performed by the preset defrost time or When defrost in

progress, Defr. LED flashes, compressor is off, and fan runs continuously.

b.After defrost, fan starts (*2) and compressor operates according to the difference between room temp,

setting temp. and temp. Threshold.

B.Elec. heater defrost (DEI-817)

a.Defrost is performed by the preset operation duty or forced manually. When defrost in progress, the

Defr. LED flashes, compressor is off, and heater turns on and fan stops.

b.After defrost, fan starts with 2 minutes delay (*2) and compressor with 1 minute delay, operates

according to the difference between room temp., setting temp. and temp. threshold.

6.Output contact capacity:

A.Compressor contact : N.O. contact 25A/250VA (*3)

B.Fan, Light, Defog, Heater contact : 7A/250VAC

7.Power requirement : AC220V/110V +/- 10% single phase 50/60 Hz, 10 Watts (Controller only)

8.Storage : -10~+70 , RH20%~80% (none-condensing)

9.Operating : -15~+60 , RH20%~90% (none-condensing)

*1. Even parameter value as 0 minute, the compressor still starts with 1 minute delay after re-plug in

*2. Fan's ON or OFF subject to continuous operating.(internal option)

*3. Compressor with 30A N.O contact plus 10A N.C contact is available..

A.Compressor-off defrost (DEI-617).

operating manually.

® w ¤· ºP ·¾ Ź

room sensor

User`s wiring

DEFOG LIGHT FAN

P4

P5

RY2

DEFROST

/LIGHT2

LIGHT

DEFOG

DEFROST COMPRESSOR

FAN

7A

P1

7A

7A

25A

25A

AC1 AC1 AC1

P6

G G

G G

P8

P9

AC1

AC2

° £ Á¹ ÷q ¼¾ ö¹ À £ Á¾ Y÷

° £ ù úq ¼¾ ö¹

· Ó © ú

· ® °

± μ¦ a½ u

· ® °

· Ó © ú

° £ Ã ú

RY1

COMP

À £ Á¾ Y÷

° £ Á\·÷Ó ©2ú

¹ q· ½2

¹ q· ½1

NFB

single phase 3W

230V SW1

~~

¶}

° £ Ã ú · Ó © ú

¶ } · Å « × ³ ] © w

· Å ® t ³ ] © w

¹ B Â à ¶ g ´ Á

° £ Ã ú ® É ¶ ¡

AC230V/

AC115V

Comments

Post a Comment